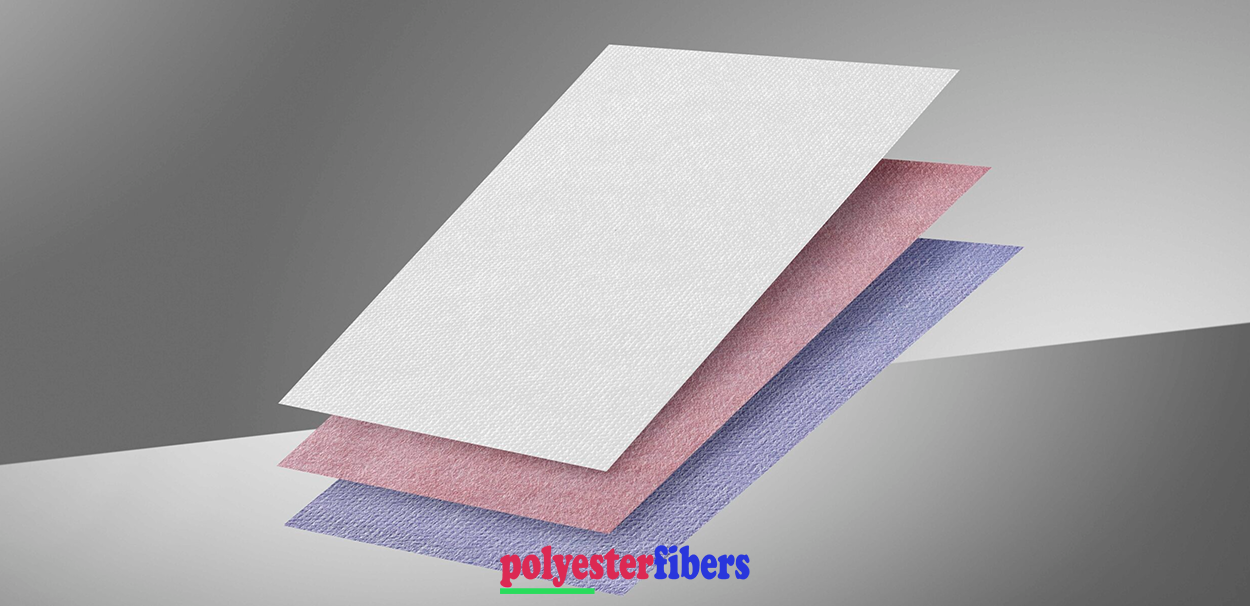

PP nonwoven, short for polypropylene nonwoven, is a fabric made from polypropylene fibers without traditional weaving or knitting processes. Its lightweight, durable, and versatile nature makes it a cornerstone material in various industries, from healthcare to agriculture and beyond.

What is PP Nonwoven?

PP nonwoven fabric is created through a bonding process where polypropylene fibers are layered and fused together using heat, pressure, or chemicals. Unlike woven fabrics, where threads are interlaced, nonwoven fabrics rely on innovative methods to achieve their structure and functionality.

This material is celebrated for its strength, moisture resistance, and adaptability, making it a preferred choice for disposable products, industrial applications, and even sustainable alternatives to single-use plastics.

Key Features of PP Nonwoven

- Lightweight: Offers excellent strength without adding bulk.

- Breathable and Moisture-Resistant: Ensures comfort while repelling water.

- Durable: Resistant to tearing, stretching, and wear.

- Cost-Effective: Affordable to produce, even at large scales.

- Eco-Friendly Options: Can be made from recycled materials and is recyclable itself.

- Customizable: Easily tailored to specific thicknesses, textures, and properties.

How is It Made?

The production process typically involves:

- Polymer Melting: Polypropylene pellets are melted into a liquid form.

- Fiber Spinning: The molten polymer is spun into fibers of various diameters.

- Web Formation: Fibers are laid out randomly or in specific orientations to form a web.

- Bonding: The fiber web is bonded using methods such as:

- Thermal Bonding: Heat and pressure are applied to fuse the fibers.

- Chemical Bonding: Adhesives or resins are used.

- Mechanical Bonding: Needle punching or hydroentangling entangles the fibers.

- Finishing: The fabric is treated for additional properties like softness, water resistance, or flame retardancy.

Applications of PP Nonwoven

1. Healthcare and Hygiene

PP nonwoven is extensively used in the medical and hygiene industries for:

- Surgical Masks and Gowns: Lightweight, breathable, and disposable protective gear.

- Diapers and Sanitary Products: Absorbent and soft layers for comfort.

- Wipes and Towels: Durable and absorbent for cleaning and personal care.

2. Agriculture

PP nonwoven is a key material in farming and gardening:

- Crop Covers: Protects plants from pests and weather extremes.

- Weed Control Mats: Suppresses weed growth while allowing water penetration.

3. Industrial Uses

In industrial settings, PP nonwoven serves multiple purposes:

- Geotextiles: Used for soil stabilization and erosion control.

- Filtration Systems: Acts as a medium in air and water filters.

- Protective Packaging: Cushions and protects fragile goods.

4. Consumer Products

PP nonwoven is found in everyday items such as:

- Reusable Shopping Bags: Lightweight and durable alternatives to single-use plastics.

- Furniture Upholstery: Provides padding and structure.

- Home Decor: Used in tablecloths, curtains, and decorative items.

Advantages of PP Nonwoven

- Affordable: Low production costs make it accessible for various applications.

- Eco-Friendly Options: Supports sustainable practices with recyclable and reusable variants.

- Hygienic: Ideal for single-use medical and hygiene products.

- Versatile: Suitable for a wide range of industries and uses.

- Fast Production: Easy and quick to manufacture at scale.

Why Choose PP Nonwoven?

PP nonwoven fabric offers the perfect blend of performance, affordability, and versatility. Its unique properties make it indispensable for industries looking to innovate while maintaining cost efficiency.

With a growing focus on sustainability, recycled and reusable PP nonwoven fabrics are paving the way for greener solutions without compromising functionality.

Whether you’re manufacturing medical supplies, agricultural products, or consumer goods, PP nonwoven provides a reliable and adaptable material for every need.

Discover the endless possibilities of PP nonwoven—a material that redefines versatility, sustainability, and innovation! 🌟

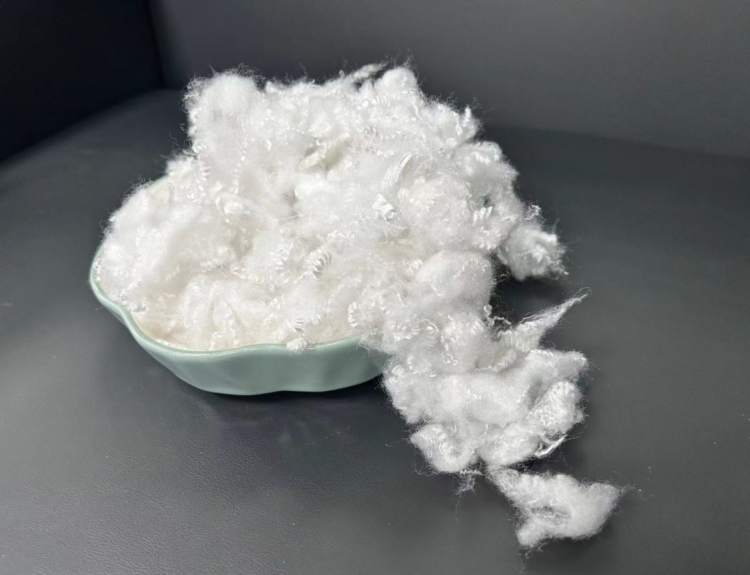

About RECYCLED POLYESTER FIBERS

POLYESTER FIBERS We partner with numerous factories and manufacturers in Viet Nam and other Asian countries.We supply various and different polyester staple fiber such as hollow conjugate siliconized and non-siliconized, hollow non conjugated fiber, hollow slick fiber, black solid fiber, brown fiber, green fiber, filling fiber, polyester fiber, recycled polyester fiber, spinning fiber. All are GRS and OEKO TEX certified.

Our polyester staple fiber is used as raw material for the production of several industrial applications such as polyester pillow filling, stuffed toys, cushion, comforters, sofa, mattress, bedding sheet, quiltings, wadding, padding, non-wovens, geotextile, automotive, abrasive products for domestic and industrial use, yarn for textile flooring (carpets and moquette), shoes, special filters and much more.

Our recycled Polyester Staple Fiber is of good quality and competitive price, which is used in the application of filling polyester pillows, mattress, cushions, quilting, comforters, padding, wadding, stuffed toys, carpets, felts, automotive nonwoven industry and home textiles.

We are well-known for our excellent customer service and we would like to have long-term business cooperation with customers from all over the world.

Please contact us for long-term cooperation!

Mr. HARRY

Website: vietnamrecycledfiber.com

Youtube: Vietnam Recycled Polyester Fiber