Polypropylene fiber, often referred to as PP fiber, is a synthetic material that has revolutionized numerous industries due to its lightweight, durable, and versatile properties. From construction to textiles and beyond, this fiber has become indispensable in applications requiring strength, chemical resistance, and cost-effectiveness.

What is Polypropylene Fiber?

Polypropylene fiber is a thermoplastic polymer derived from propylene gas. The fibers are produced through a process of polymerization, extrusion, and stretching, resulting in a material with high tensile strength and exceptional performance under various conditions.

Polypropylene fiber’s inherent resistance to moisture, chemicals, and abrasion makes it ideal for a wide range of uses across industries.

Key Applications of Polypropylene Fiber

1. Construction Industry

Polypropylene fiber plays a critical role in enhancing the durability and functionality of construction materials:

- Concrete Reinforcement: Improves tensile strength and prevents cracking by distributing stress evenly.

- Plaster and Mortar: Enhances binding and reduces shrinkage.

- Geotextiles: Stabilizes soil, controls erosion, and provides drainage solutions.

2. Textiles and Fabrics

PP fiber is widely used in the production of textiles due to its lightweight and moisture-resistant properties:

- Carpets and Rugs: Durable, stain-resistant, and cost-effective.

- Nonwoven Fabrics: Used in hygiene products, filters, and industrial applications.

- Sportswear: Provides moisture-wicking and quick-drying capabilities.

3. Automotive Industry

In automotive applications, polypropylene fiber offers strength and lightweight advantages:

- Car Mats and Upholstery: Resistant to wear and easy to clean.

- Soundproofing: Acts as an acoustic insulator in vehicle interiors.

- Thermal Insulation: Provides heat resistance in various components.

4. Industrial Uses

Polypropylene fiber supports industrial operations with its durability and chemical resistance:

- Ropes and Nets: Strong yet lightweight materials for marine and agricultural uses.

- Filtration Systems: Acts as a filtration medium for water and air purification.

- Packaging: Used in woven sacks and straps for heavy-duty packaging.

5. Agriculture and Horticulture

In agriculture, polypropylene fiber contributes to improved farming efficiency and sustainability:

- Crop Covers: Protects plants from pests, frost, and harsh weather.

- Weed Mats: Prevents weed growth while allowing water and nutrients to reach the soil.

- Twines and Ropes: Supports plant growth and assists in harvesting processes.

6. Consumer Goods

Polypropylene fiber enhances the functionality and durability of everyday items:

- Reusable Shopping Bags: Eco-friendly and long-lasting alternatives to plastic bags.

- Household Items: Cleaning brushes, mops, and furniture padding.

- Toys and Crafts: Provides lightweight filling and structural support.

Advantages of Polypropylene Fibers

- Durable: Resistant to wear, chemicals, and UV exposure.

- Lightweight: Ideal for applications requiring portability and ease of handling.

- Cost-Effective: Affordable and efficient to produce.

- Moisture-Resistant: Retains properties in wet conditions.

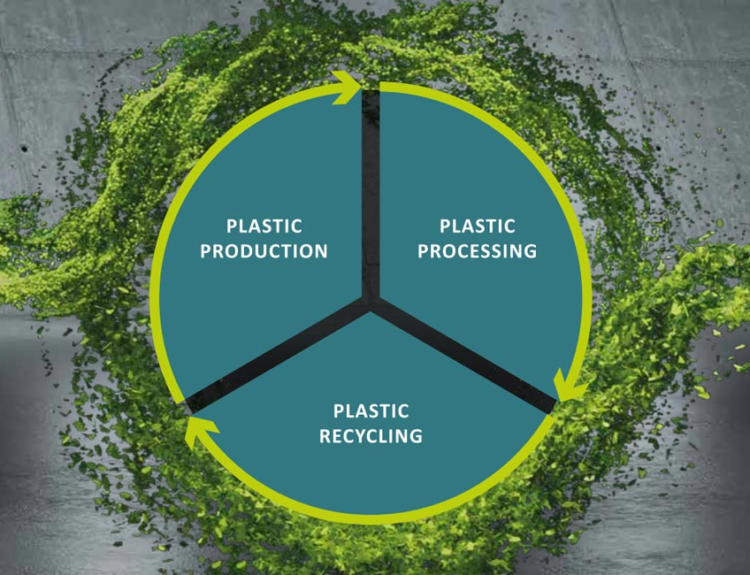

- Eco-Friendly Options: Recyclable variants support sustainable practices.

Future of Polypropylene Fiber Applications

As industries push for sustainability and innovation, polypropylene fiber continues to evolve with eco-friendly production methods and advanced engineering. Recycled polypropylene fiber is gaining traction as a green alternative, offering the same durability and versatility with reduced environmental impact.

Why Polypropylene Fiber is Essential

Polypropylene fiber’s combination of strength, flexibility, and affordability makes it a vital material in modern manufacturing and construction. Its diverse applications demonstrate its ability to adapt to the needs of various industries while maintaining high performance.

Whether you’re reinforcing concrete, crafting textiles, or producing durable consumer goods, polypropylene fiber offers a reliable and versatile solution.

Explore the possibilities of polypropylene fiber—a material that blends innovation, efficiency, and sustainability to meet the demands of the future! 🌟

About RECYCLED POLYESTER FIBERS

POLYESTER FIBERS We partner with numerous factories and manufacturers in Viet Nam and other Asian countries.We supply various and different polyester staple fiber such as hollow conjugate siliconized and non-siliconized, hollow non conjugated fiber, hollow slick fiber, black solid fiber, brown fiber, green fiber, filling fiber, polyester fiber, recycled polyester fiber, spinning fiber. All are GRS and OEKO TEX certified.

Our polyester staple fiber is used as raw material for the production of several industrial applications such as polyester pillow filling, stuffed toys, cushion, comforters, sofa, mattress, bedding sheet, quiltings, wadding, padding, non-wovens, geotextile, automotive, abrasive products for domestic and industrial use, yarn for textile flooring (carpets and moquette), shoes, special filters and much more.

Our recycled Polyester Staple Fiber is of good quality and competitive price, which is used in the application of filling polyester pillows, mattress, cushions, quilting, comforters, padding, wadding, stuffed toys, carpets, felts, automotive nonwoven industry and home textiles.

We are well-known for our excellent customer service and we would like to have long-term business cooperation with customers from all over the world.

Please contact us for long-term cooperation!

Mr. HARRY

Website: vietnamrecycledfiber.com

Youtube: Vietnam Recycled Polyester Fiber