- 1. Versatility and Ubiquity of PET Plastic:

- 2. The Linear Economy Challenge:

- 3. PET Plastic Transition to a Circular Economy:

- 4. Recycling PET Plastic:

- 5. Applications PET Plastic Beyond Packaging:

- 6. Consumer Awareness and Responsibility:

- 7. Challenges and Innovations:

- 8. Collaborative Efforts:

- Conclusion: From Waste to Resource

- About POLYESTER FIBERS

In the global pursuit of sustainable practices, the circular economy has emerged as a guiding principle, promoting resource efficiency, reduced waste, and environmental stewardship. Within this paradigm, PET (polyethylene terephthalate) plastic plays a pivotal role, exemplifying the potential for creating a closed-loop system that transforms waste into valuable resources. Let’s explore the multifaceted role of PET plastic in fostering a circular economy.

1. Versatility and Ubiquity of PET Plastic:

- Key Contributor to Packaging: PET plastic is widely utilized in the packaging industry, finding its way into bottles, containers, and various forms of packaging for beverages, food products, personal care items, and more. Its popularity is attributed to its transparency, lightweight nature, and resilience.

2. The Linear Economy Challenge:

- Origin in a Linear Economy: Historically, the production and consumption of plastic, including PET, followed a linear economy model—a “take, make, dispose” approach. This resulted in significant environmental challenges, including plastic pollution, resource depletion, and a growing burden on landfills.

3. PET Plastic Transition to a Circular Economy:

- Designing for Circular Principles: The circular economy envisions a departure from the linear model by prioritizing circular principles, namely recycling, reusing, and reducing waste. In this context, PET plastic becomes a focal point for transformative change.

4. Recycling PET Plastic:

Closed-Loop Recycling: PET plastic is highly recyclable, making it a cornerstone in closed-loop recycling systems. The recycling process involves collecting post-consumer PET items, such as bottles, and processing them to create recycled PET (rPET) material. This material can then be used to manufacture new products, including bottles, textiles, and packaging.

Reducing Dependency on Virgin Resources: The use of rPET in manufacturing reduces the demand for virgin PET resin derived from fossil fuels. This not only conserves natural resources but also curtails the carbon footprint associated with traditional PET production.

5. Applications PET Plastic Beyond Packaging:

Textiles and Apparel: rPET is increasingly being employed in the textile and apparel industry to create sustainable fabrics. The conversion of PET plastic bottles into polyester fibers for clothing exemplifies the circular journey of this material.

Construction and Manufacturing: rPET finds applications in the construction sector, where it can be used in insulation, carpeting, and other building materials. It is also utilized in the manufacturing of various consumer goods, extending the lifespan of PET plastic.

6. Consumer Awareness and Responsibility:

- Driving Demand for Sustainable Choices: Growing consumer awareness of environmental issues is driving demand for sustainable products. Brands and manufacturers responding to this demand by incorporating recycled PET in their offerings are contributing to a circular economy while aligning with consumer values.

7. Challenges and Innovations:

- Contamination and Technological Advances: Challenges such as contamination in recycling streams highlight the need for improved waste management practices. Ongoing technological advancements, including better sorting technologies and processes, aim to enhance the efficiency of PET recycling.

8. Collaborative Efforts:

- Industry Collaboration: The transition to a circular economy requires collaboration across industries, governments, and communities. Initiatives that promote the collection, recycling, and repurposing of PET plastic are often collaborative efforts involving stakeholders at various levels.

Conclusion: From Waste to Resource

In the circular economy, PET plastic transforms from being a potential environmental burden to a valuable resource. The closed-loop system that recycling facilitates ensures that PET’s journey is not a linear one but a continuous cycle of use, recycling, and reuse. As the role of PET in the circular economy expands, it becomes a symbol of how conscious choices and collaborative efforts can drive positive environmental change. Embracing the circular principles embodied by PET plastic signifies not just a shift in material use but a commitment to a regenerative and sustainable future.

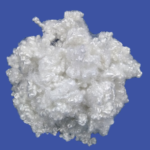

About POLYESTER FIBERS

POLYESTER FIBERS We partner with numerous factories and manufacturers in Viet Nam and other Asian countries.We supply various and different polyester staple fiber such as hollow conjugate siliconized and non-siliconized, hollow non conjugated fiber, hollow slick fiber, black solid fiber, brown fiber, green fiber, filling fiber, polyester fiber, recycled polyester fiber, spinning fiber. All are GRS and OEKO TEX certified.

Our polyester staple fiber is used as raw material for the production of several industrial applications such as polyester pillow filling, stuffed toys, cushion, comforters, sofa, mattress, bedding sheet, quiltings, wadding, padding, non-wovens, geotextile, automotive, abrasive products for domestic and industrial use, yarn for textile flooring (carpets and moquette), shoes, special filters and much more.

Our recycled Polyester Staple Fiber is of good quality and competitive price, which is used in the application of filling polyester pillows, mattress, cushions, quilting, comforters, padding, wadding, stuffed toys, carpets, felts, automotive nonwoven industry and home textiles.

We are well-known for our excellent customer service and we would like to have long-term business cooperation with customers from all over the world.

Please contact us for long-term cooperation!

Mr. HARRY

Website: vietnamrecycledfiber.com

Youtube: Vietnam Recycled Polyester Fiber