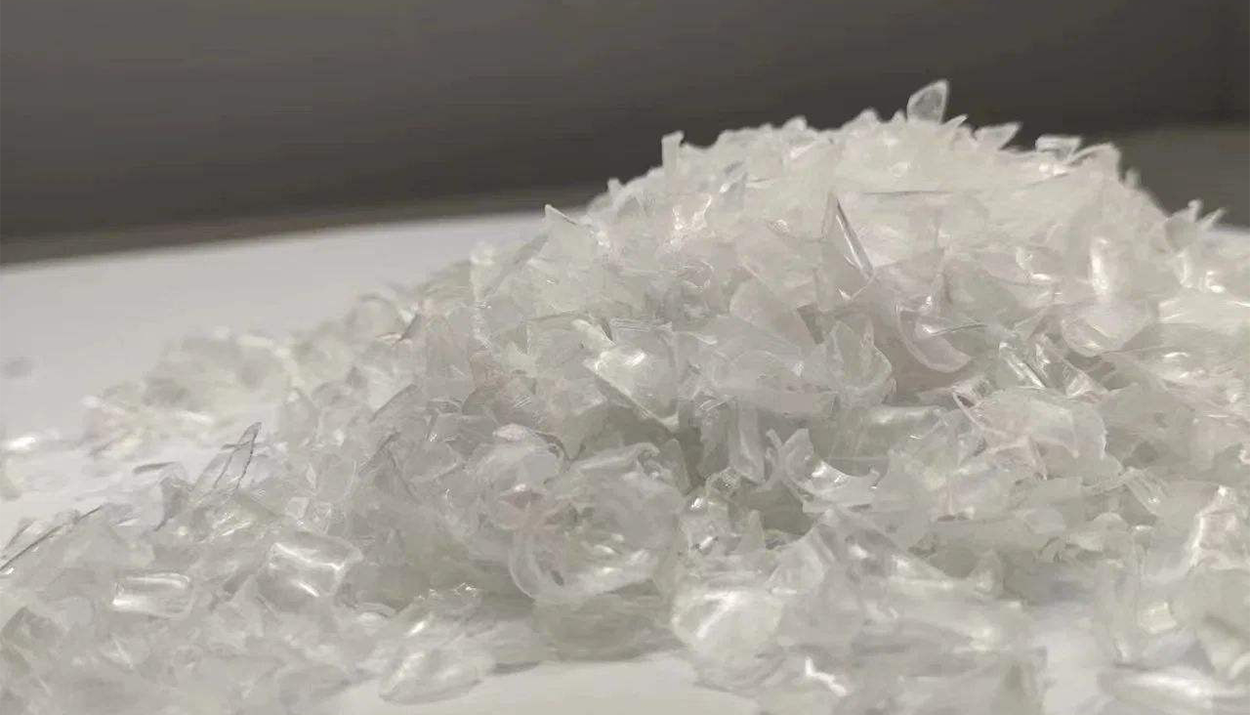

In the realm of recycling and sustainable materials, PET flakes stand as a shining example of circular innovation. Derived from post-consumer PET (polyethylene terephthalate) bottles, PET flakes undergo a meticulous process that transforms them into a versatile and eco-friendly material. Let’s embark on the fascinating journey of PET flakes, exploring their applications, environmental impact, and the role they play in shaping a more sustainable future.

1. Origins of PET Flakes:

- Post-Consumer PET Bottles: The journey of PET flake begins with post-consumer PET bottles collected from recycling programs. These bottles, commonly used for beverages and other liquid products, serve as the primary source of post-consumer PET material.

2. Collection and Sorting:

- Recycling Facilities: Post-consumer PET bottles are transported to recycling facilities, where they undergo a meticulous sorting process. Advanced technologies and manual sorting help separate PET bottles from other materials, ensuring a clean stream for recycling.

3. Cleaning and Shredding:

Removal of Contaminants: To prepare the bottles for recycling, they undergo thorough cleaning. Labels, caps, and any remaining liquid are removed, and the bottles are washed to eliminate contaminants.

Shredding Process: After cleaning, the PET bottles are shredded into small pieces, creating what is known as PET flakes. These flakes are the raw material for the next phase of the recycling journey.

4. Pelletizing PET Flakes:

Melting and Extrusion: The PET flake are then subjected to a melting and extrusion process. This involves heating the flakes to their melting point and then extruding the molten material through small openings to form thin strands.

Cutting into Pellets: The extruded strands are cooled and cut into small pellets. These PET pellets are the building blocks for a wide range of applications.

5. Applications of PET Flakes:

Textile Industry: One prominent application of PET flake is in the textile industry. The pellets can be further processed to create recycled polyester fibers, which are used in the production of sustainable fabrics for clothing and other textiles.

Packaging Materials: PET flakes can be used to create new packaging materials, continuing the circular loop. Recycled PET is commonly used for food and beverage packaging, reducing the demand for virgin plastic.

Construction Materials: Innovations in recycling technology have led to the use of PET flakes in construction materials, such as insulation and building components, contributing to sustainable building practices.

Films and Sheets: PET flakes can be processed into films and sheets, suitable for various applications, including signage, displays, and stationery products.

6. Environmental Impact:

Reducing Resource Depletion: The use of PET flakes in manufacturing reduces the demand for virgin PET resin derived from fossil fuels. This contributes to resource conservation and minimizes the environmental impact associated with traditional plastic production.

Waste Diversion: By recycling PET bottles into flakes, the process diverts plastic waste from landfills and incineration, offering an effective waste management solution.

7. Challenges and Innovations:

Contamination Concerns: Contamination in the recycling stream remains a challenge, impacting the quality of PET flakes. Ongoing innovations in sorting technologies and improved collection systems aim to address this issue.

Technological Advancements: Advancements in recycling technologies are continually expanding the applications of PET flakes, making them suitable for a broader range of products and industries.

8. Consumer Awareness:

- Driving Demand for Recycled Products: Growing consumer awareness and demand for sustainable products are driving industries to incorporate recycled materials, including PET flakes, into their offerings. This shift in consumer behavior encourages businesses to adopt more environmentally friendly practices.

Conclusion: A Sustainable Cycle Unveiled

The journey of PET flake encapsulates the essence of a circular economy, where waste is transformed into a valuable resource. From bottles to versatile pellets, PET flakes showcase the potential for creating sustainable solutions across various industries. As technologies advance and awareness grows, the role of PET flakes in shaping a more sustainable and circular future becomes increasingly prominent. Embracing the transformative journey of PET flakes signifies not just a recycling process but a commitment to reducing environmental impact and fostering a regenerative approach to material use.

About POLYESTER FIBERS

POLYESTER FIBERS We partner with numerous factories and manufacturers in Viet Nam and other Asian countries.We supply various and different polyester staple fiber such as hollow conjugate siliconized and non-siliconized, hollow non conjugated fiber, hollow slick fiber, black solid fiber, brown fiber, green fiber, filling fiber, polyester fiber, recycled polyester fiber, spinning fiber. All are GRS and OEKO TEX certified.

Our polyester staple fiber is used as raw material for the production of several industrial applications such as polyester pillow filling, stuffed toys, cushion, comforters, sofa, mattress, bedding sheet, quiltings, wadding, padding, non-wovens, geotextile, automotive, abrasive products for domestic and industrial use, yarn for textile flooring (carpets and moquette), shoes, special filters and much more.

Our recycled Polyester Staple Fiber is of good quality and competitive price, which is used in the application of filling polyester pillows, mattress, cushions, quilting, comforters, padding, wadding, stuffed toys, carpets, felts, automotive nonwoven industry and home textiles.

We are well-known for our excellent customer service and we would like to have long-term business cooperation with customers from all over the world.

Please contact us for long-term cooperation!

Mr. HARRY

Website: vietnamrecycledfiber.com

Youtube: Vietnam Recycled Polyester Fiber