As the world grapples with the challenges of plastic waste and environmental sustainability, a transformative concept gaining momentum is the Circular Economy. Within this framework, PET (Polyethylene Terephthalate) plastic has emerged as a key player, playing a pivotal role in reshaping our approach to plastic use, disposal, and recycling.

Understanding the Circular Economy: A Paradigm Shift

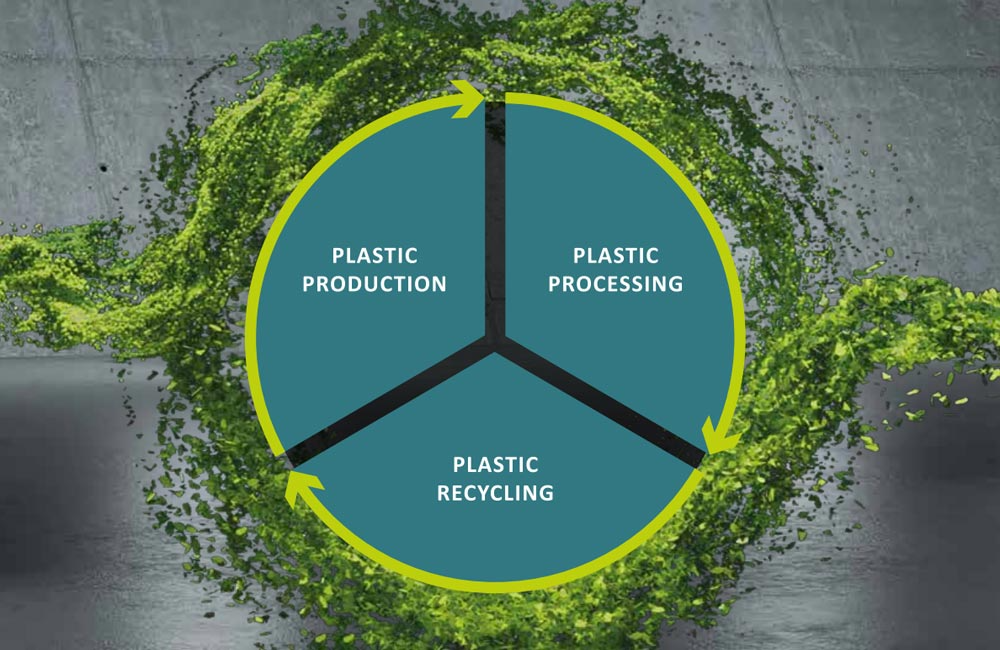

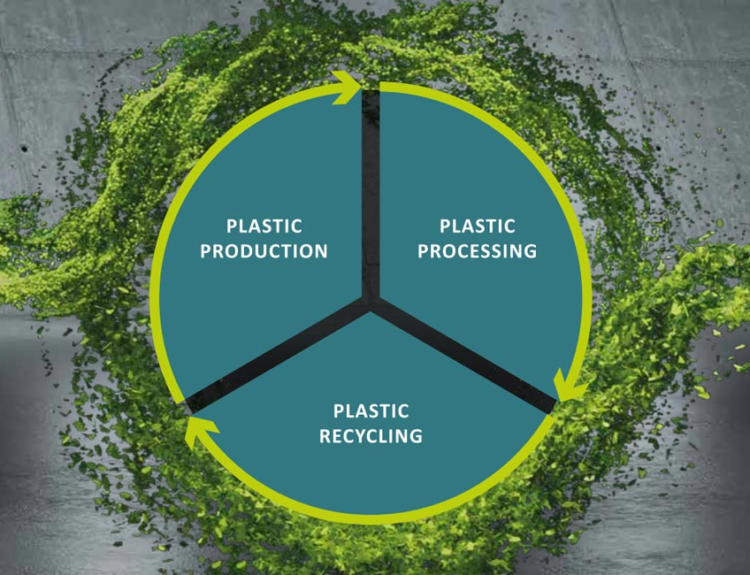

The Circular Economy stands in stark contrast to the traditional linear model of “take, make, dispose.” Instead, it envisions a closed-loop system where materials are reused, refurbished, remanufactured, and recycled to minimize waste and environmental impact. PET plastic, with its versatility and recyclability, aligns seamlessly with the principles of the Circular Economy.

The Versatility of PET Plastic:

Packaging Revolution: PET plastic is widely used in the packaging industry due to its lightweight, durable, and transparent qualities. From beverage bottles to food containers, PET packaging has become ubiquitous. Its high recyclability makes it a valuable resource in creating sustainable packaging solutions.

Textiles and Apparel: Beyond packaging, PET plastic finds new life in the textile industry. Recycled PET, often labeled as rPET, is transformed into fibers used in the production of clothing, bags, and other textile products. This not only reduces the demand for virgin polyester but also mitigates the environmental impact of textile production.

Construction and Automotive Applications: PET plastic’s resilience and strength make it suitable for applications in construction and automotive industries. Recycled PET can be used in the manufacturing of carpets, insulation, and even components in automobiles, contributing to resource conservation.

The Recycling Journey of PET Plastic:

Collection: The first step in the circular journey of PET plastic involves efficient collection systems. Recycling initiatives, bottle deposit programs, and waste management efforts play a crucial role in gathering used PET items.

Sorting and Cleaning: Once collected, PET plastic goes through a meticulous sorting and cleaning process. Separating it from other materials ensures a higher quality of recycled PET, ready for the next phase.

Processing and Repurposing: Recycled PET is then processed, melted, and transformed into pellets or flakes. These materials can be used in various industries, including packaging, textiles, and manufacturing, creating a closed loop where PET plastic gets a second life.

Environmental Benefits:

Reduced Carbon Footprint: Recycling PET plastic consumes less energy compared to producing virgin PET. This reduction in energy consumption translates to a lower carbon footprint, contributing to overall environmental sustainability.

Waste Reduction: By integrating PET plastic into the Circular Economy, the amount of plastic waste destined for landfills or incineration decreases. Recycling PET reduces the burden on natural resources and minimizes environmental harm.

Challenges and Future Outlook:

While the Circular Economy model holds immense promise, challenges such as improving recycling infrastructure, consumer education, and design for recyclability must be addressed. Innovations in recycling technologies and increased collaboration among stakeholders will be instrumental in overcoming these challenges.

Conclusion: PET Plastic as a Catalyst for Change

As we navigate the complex landscape of plastic use and waste, PET plastic emerges not just as a material but as a catalyst for change. Its inherent recyclability and versatility make it a cornerstone in the Circular Economy, showcasing the potential for a more sustainable and responsible approach to plastic consumption. By recognizing the role of PET plastic in closing the loop, we take a significant step towards a future where plastic is viewed not as waste but as a valuable resource within a circular and regenerative system.

About RECYCLED POLYESTER FIBERS

POLYESTER FIBERS We partner with numerous factories and manufacturers in Viet Nam and other Asian countries.We supply various and different polyester staple fiber such as hollow conjugate siliconized and non-siliconized, hollow non conjugated fiber, hollow slick fiber, black solid fiber, brown fiber, green fiber, filling fiber, polyester fiber, recycled polyester fiber, spinning fiber. All are GRS and OEKO TEX certified.

Our polyester staple fiber is used as raw material for the production of several industrial applications such as polyester pillow filling, stuffed toys, cushion, comforters, sofa, mattress, bedding sheet, quiltings, wadding, padding, non-wovens, geotextile, automotive, abrasive products for domestic and industrial use, yarn for textile flooring (carpets and moquette), shoes, special filters and much more.

Our recycled Polyester Staple Fiber is of good quality and competitive price, which is used in the application of filling polyester pillows, mattress, cushions, quilting, comforters, padding, wadding, stuffed toys, carpets, felts, automotive nonwoven industry and home textiles.

We are well-known for our excellent customer service and we would like to have long-term business cooperation with customers from all over the world.

Please contact us for long-term cooperation!

Mr. HARRY

Website: vietnamrecycledfiber.com

Youtube: Vietnam Recycled Polyester Fiber